Helping You Streamline Your Industrial Processes

Design, Manufacturing & Installation of Process Systems

Our team at Atlas Automation is dedicated to providing cutting-edge solutions for process systems that redefine efficiency and productivity. With a focus on precision engineering and tailored strategies, we bring a wealth of expertise to optimize your industrial processes. Specializing in serving clients in the food process industry in Rochester, Buffalo, Syracuse NY, and beyond, we take pride in our collaborative approach to delivering comprehensive process solutions that are delivered on time, on budget, and exceed expectations.

Process Design

Our process engineering staff specializes in food-grade fluid process applications. We have the experience to design and implement production process systems and CIP equipment at the highest level. We can work from pre-engineered design packages, create conceptual drawings from customer input, or fully design and engineer your next project from concept to installation to completion. This allows you total flexibility throughout the engineering phase.

Process Design Capabilities

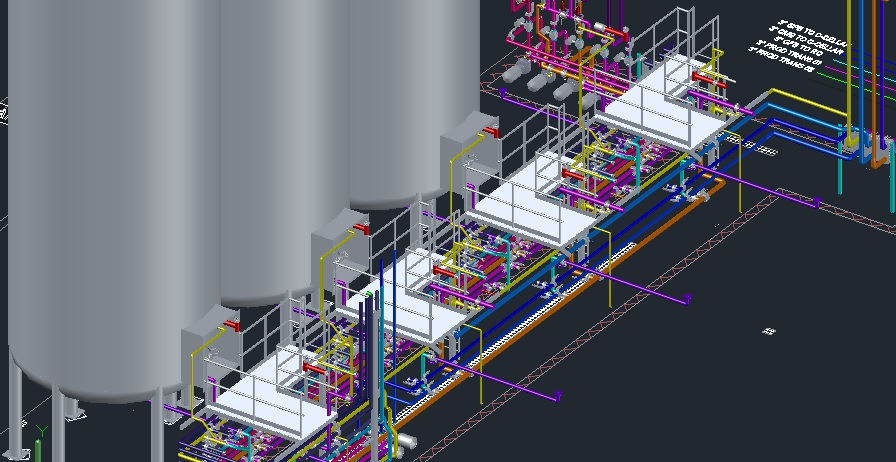

- 2D & 3D AutoCAD

- Process Design

- Skid Package Design

- Bid Packages

- P&ID System Development

- P&ID Plant Development

- Functional Specifications

- Process System Layout Drawings

Process Mechanical & Sanitary Welding

We specialize in sanitary welding and the installation of piping systems, skidded systems, design and build of pasteurization and CIP systems as well as blending/batching and product transfer. Atlas Automation is a 3-A, FDA & PMO-compliant manufacturer of Sanitary Process Equipment.

We also custom fabricate stainless platforms, walkways, and sanitary sheet metal equipment, and design and build ancillary support products: (COP Tubs, Flow Plates, Carts, Lab Tables, Accumulation Tables, etc.)

Process Mechanical & Sanitary Welding Capabilities

- CIP Systems

- RO & Filtration

- Valve Clusters

- Hot Water Sets

- Flow Plates

- Cooking / Heating

- HTST & UHT Systems

- Sanitary Welding / Pipe Installation

- Pump Carts

- Stainless Mezzanines & Walkways

- Aseptic Equipment Installation & Integration

- Blending / Batching Systems

Field Welding Services

- Orbital

- TIG

- MIG

- Carbon Steel Pipe

- Structural

Process Skid Packaging

Atlas Automation can design and manufacture sanitary processes and cleaning equipment to meet PMO, 3A, and FDA food-grade standards. All equipment is built in our shop by seasoned tradesmen who have the experience and expertise to produce high-quality skidded or build-in-place stainless process systems.

Clean-in-Place (CIP) Systems

A cleaning-in-place system is designed to assist in cleaning and disinfecting during the production process. A CIP system can help an organization save money while increasing production, as it reduces the labor involved in cleaning.

Your CIP system can be either automated or manually operated, and our team can design a system to ensure your facility meets strict hygiene requirements without breaking down components for cleaning and reassembly.

Atlas Automation offers turn-key services and custom engineering solutions. We manufacture CIP systems with automated controls and provide complete services including installation, and startup.

HTST & UHT Pasteurization Process Systems

Atlas specializes in the design and manufacturing of HTST & UHT pasteurization process equipment. Custom-designed applications can be installed to fit your specific needs, regardless of size or complexity.

Our food process experience includes all forms of product handling such as cooking, pasteurizing, homogenizing, filling, transfer, and packaging integration. We create skid-based systems designed for cost-effective implementation, operation, and ease of maintenance.

This includes:

- Pasteurization Equipment

- Brewing / Fermenting Equipment

- Aseptic Processing

- Blending/ Batching Packages

- Pumping / Product Transfer & Storage

- UV Sterilization Equipment

Field Installation

Our highly skilled tradesmen can be dispatched to your facility for not only capital projects but also maintenance and repair, component replacement, retrofits, platforms/ walkways, or any sanitary welding application. Our company is headquartered in Rochester, NY. We can provide our installation services to clients in Buffalo and Syracuse, NY, and beyond.

Field Installation Services

- Sanitary Welding

- Sanitary Process Piping

- Skidded Systems

- Stainless Fabrication

- System Maintenance & Troubleshooting

- Equipment Placement & Integration

- Valve, Pump & Instrumentation Installation

- Mixproof Valve Applications Expertise

- Retrofits/Maintenance/Repair

- Complete Turn-Key Process System Installation

- Custom On-Demand Applications

- Custom Stainless Fabrication

- Piping Insulation & Heat Trace

Certified & Trusted To Maintain Sanitary Standards

- NYS-certified installer of sanitary piping systems

- Registered by the Department of Agriculture and Markets as a NYS dairy equipment installer

- Compliant with all food-grade standards

To get a quote or inquire about maintenance or repair services for your process systems, please contact Atlas Automation at 585-227-1110!